Solar yield prediction: what are the key factors ?

The annual yield of a photovoltaic system depends on many factors, not all of which are equally influential. Some are first order, others second or even third-order.

The purpose of this article is to address some of the most important ones, from the incident irradiation on the modules, to the injection into the grid (when this is the case), as illustrated by the losses breakdown as it appears in archelios PRO.

Irradiation

The first group of losses relates to irradiation. Only mask losses, which have been discussed in detail in a previous article-> Shadings and photovoltaic potential.

The first group of losses relates to irradiation. Only mask losses, which have been discussed in detail in a previous article-> Shadings and photovoltaic potential.

These losses relate to the solar resource where the installation is located. The data is collected from a meteorological file, based on ground measurements taken over a period of several years (typically 15 to 20 years), or from databases established from satellite pictures.

We should keep in mind that the objective of a yield study is to estimate the production of a photovoltaic installation over its lifetime. As the future irradiation is not available, the implicit assumption of the study is that solar irradiation observed in the past will be observed in the future. To lower the effects of inter-annual variations, the time span of the data must be large enough.

Even before the simulation, the solar resource thus constitutes a first source of uncertainty, which has to be taken into account.

Bifacial modules

For bifacial modules, the calculation of the irradiation received by the modules involves additional parameters:

- The albedo of the ground (fraction of solar energy that is reflected), a parameter that is already present in the case of monofacial modules, but with less influence, except in special cases (high slope, snow).

- The geometry of the plant: spacing between rows of modules, height in relation to the ground, tilt.

Irradiation loss received by the modules

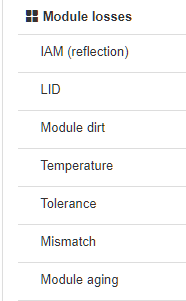

Two loss factors affect the irradiation received by the modules, which is not the irradiation received by the cells that compose them

- Soiling, which is estimated to represent a loss of up to 4% in temperate latitudes with regular rainfall. It can be much higher (and difficult to estimate precisely) depending on the location of the plant (e.g. proximity to a quarry or seasonal agricultural activity). It can be reduced by regular cleaning, the gain of which is difficult to assess.

- Reflection losses, often called IAM (Incidence Angle Modifier). These losses are higher for orientations and tilts that imply high angles of incidence of the sun’s rays.

Temperature losses are often the most important item at module level. They depend on the incident irradiation and the ambient temperature. These losses are significant when the ventilation at the back of the modules is poor due to the installation on the roof (“applied” or “integrated”). The loss linked to ageing of the modules is particular because of an evolution over the time. It is not to be neglected since it is often observed that this loss, averaged over the lifetime of the plant, is mostly at the module level.

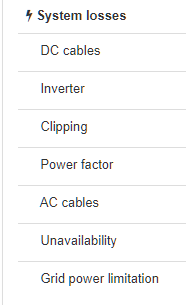

System losses

System losses can be reduced with a suitable sizing. Cables are sized to limit losses to 1% under STC conditions on the DC side, but also on the AC side. Beyond the intrinsic performance of the inverter (nominal efficiency and part-load efficiencies), poor sizing can lead to significant losses which can be evaluated: clipping, optimal operating point outside the MPP range of the inverter. Conforming to the validity indicators displayed during the system definition allows to limit these losses.

Uncertainty, as mentioned for the solar resource, is also important, since each parameter and each simulation step is associated with an uncertainty. Taking these uncertainties into account usually results in the calculation of a P90 (or PXX) deliverable, the meaning of which is as follows: the probability of having a yield value greater than P90 is 90%.

Beyond the model/software used and its accuracy, the “user” factor is at least also important:

- Setting the parameters of the software requires to know each parameter with its meaning and its influence in the model.

- Furthermore, justifying the hypothesis is, for the funders, just as important as the model/software used to carry out the study.

Design, simulate and analyse your photovoltaic project.

Depending on whether you are a designer, small project installer, solar power plant developer or occasional user, you will not need the same functionality. With the new archelios™ Pro range, you have an ergonomic and high-performance tool, adapted to the size of your projects with functionalities tailored to your needs.

With archelios™, design any photovoltaic project, from a rooftop to big solar plants, obtaining a precise production forecast, detailed losses and economic indicators.

Feasibility and profitability study, simulation, production calculation, complete electrical dimensioning, the software is designed for all types of projects.

Article written by Ismaël LOKHAT, Scientific Manager – Cythelia Energy

Do you want to know more?

Trace Software – empowering electrical solutions.

Webinars eSHOP Service commercial